Industrial engineers are versatile professionals who play a crucial role in designing, optimizing, and improving the efficiency of systems, processes, and organizations. Their expertise spans across various industries, including manufacturing, healthcare, finance, and logistics, making them highly sought after in today’s fast-paced and competitive market. With a strong foundation in mathematics, physics, and social sciences, industrial engineers are equipped to analyze complex problems, identify areas for improvement, and develop innovative solutions that enhance productivity, reduce costs, and improve overall performance.

Key Responsibilities of Industrial Engineers

Industrial engineers are responsible for a wide range of tasks, including designing and implementing new systems, processes, and technologies, as well as analyzing and optimizing existing ones. They use various tools and techniques, such as simulation modeling, data analytics, and lean manufacturing principles, to identify bottlenecks, reduce waste, and improve workflow efficiency. Some of the key responsibilities of industrial engineers include:

- Process Improvement: Identifying areas for improvement and developing strategies to increase efficiency, reduce costs, and enhance productivity.

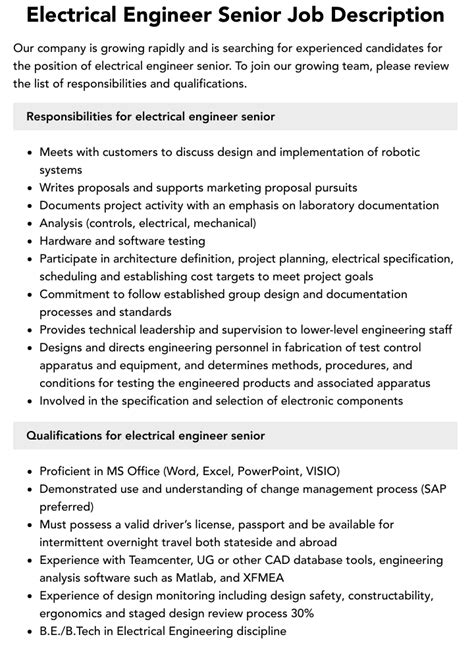

- System Design: Designing and implementing new systems, processes, and technologies to improve performance and meet organizational goals.

- Operations Research: Using advanced analytical techniques, such as linear programming and dynamic simulation, to analyze complex problems and develop optimal solutions.

- Quality Control: Developing and implementing quality control systems to ensure that products and services meet customer requirements and industry standards.

Applications of Industrial Engineering

Industrial engineering has a wide range of applications across various industries, including:- Manufacturing: Industrial engineers work in manufacturing to design and optimize production systems, improve product quality, and reduce costs.

- Healthcare: Industrial engineers work in healthcare to improve patient flow, reduce wait times, and optimize resource allocation.

- Finance: Industrial engineers work in finance to develop risk management strategies, optimize investment portfolios, and improve operational efficiency.

- Logistics: Industrial engineers work in logistics to optimize supply chain operations, reduce transportation costs, and improve delivery times.

| Industry | Applications |

|---|---|

| Manufacturing | Production system design, quality control, supply chain optimization |

| Healthcare | Patient flow optimization, resource allocation, quality improvement |

| Finance | Risk management, investment portfolio optimization, operational efficiency |

| Logistics | Supply chain optimization, transportation management, delivery time reduction |

Key Points

- Industrial engineers are versatile professionals with a strong foundation in mathematics, physics, and social sciences.

- They are responsible for designing, optimizing, and improving the efficiency of systems, processes, and organizations.

- Industrial engineers have a wide range of applications across various industries, including manufacturing, healthcare, finance, and logistics.

- They use various tools and techniques, such as simulation modeling, data analytics, and lean manufacturing principles, to identify bottlenecks and improve workflow efficiency.

- Industrial engineers have the unique ability to combine technical knowledge with business acumen, making them highly effective in a wide range of industries and applications.

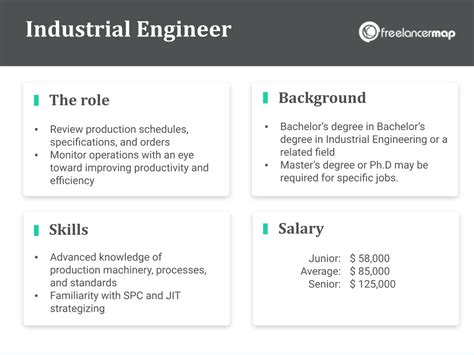

Education and Training

To become an industrial engineer, one typically needs to earn a bachelor’s degree in industrial engineering or a related field, such as mechanical engineering, electrical engineering, or computer science. Coursework in industrial engineering programs typically includes classes in mathematics, statistics, computer programming, and engineering principles, as well as specialized courses in areas such as operations research, quality control, and supply chain management. Many industrial engineers also choose to pursue advanced degrees, such as master’s or doctoral degrees, to further their knowledge and career prospects.

Certifications and Professional Development

Industrial engineers can obtain various certifications to demonstrate their expertise and commitment to the field. Some common certifications include:- Certified Industrial Engineer (CIE): Offered by the Institute of Industrial and Systems Engineers (IISE), this certification recognizes industrial engineers who have demonstrated expertise in the field.

- Certified Supply Chain Professional (CSCP): Offered by the Association for Supply Chain Management (ASCM), this certification recognizes professionals who have demonstrated expertise in supply chain management.

- Lean Six Sigma Certification: Offered by various organizations, this certification recognizes professionals who have demonstrated expertise in lean manufacturing and Six Sigma principles.

What is the role of an industrial engineer in a manufacturing company?

+Industrial engineers in manufacturing companies are responsible for designing and optimizing production systems, improving product quality, and reducing costs. They use various tools and techniques, such as simulation modeling and lean manufacturing principles, to identify bottlenecks and improve workflow efficiency.

What skills do industrial engineers need to succeed in their careers?

+Industrial engineers need to have strong analytical and problem-solving skills, as well as excellent communication and teamwork skills. They must be able to analyze complex problems, identify areas for improvement, and develop innovative solutions that enhance productivity and reduce costs.

What are some of the challenges faced by industrial engineers in their careers?

+Industrial engineers face various challenges in their careers, including the need to stay up-to-date with new technologies and trends, managing complex projects and teams, and balancing technical and business requirements. They must also be able to communicate effectively with stakeholders and navigate organizational politics.

In conclusion, industrial engineers play a vital role in designing, optimizing, and improving the efficiency of systems, processes, and organizations. With their strong foundation in mathematics, physics, and social sciences, they are equipped to analyze complex problems, identify areas for improvement, and develop innovative solutions that enhance productivity, reduce costs, and improve overall performance. As the demand for industrial engineers continues to grow, it is essential for professionals in this field to stay up-to-date with new technologies and trends, develop strong analytical and problem-solving skills, and cultivate excellent communication and teamwork skills.