Industrial engineers are professionals who specialize in designing, optimizing, and implementing systems, processes, and facilities to improve efficiency, productivity, and quality. They use a combination of technical knowledge, business acumen, and analytical skills to identify opportunities for improvement and develop solutions that benefit organizations and society as a whole. With a strong foundation in mathematics, physics, and engineering principles, industrial engineers are equipped to tackle complex problems in a wide range of industries, from manufacturing and logistics to healthcare and finance.

One of the key aspects of industrial engineering is the focus on systems thinking. Industrial engineers consider the entire system, including people, materials, equipment, and energy, to design and improve processes that meet specific goals and objectives. This holistic approach enables them to identify areas of inefficiency, waste, and variability, and develop targeted interventions to address these issues. By applying principles of engineering, statistics, and computer science, industrial engineers can create models, simulations, and algorithms to analyze and optimize complex systems.

Key Points

- Industrial engineers design and optimize systems, processes, and facilities to improve efficiency and productivity

- They use a combination of technical knowledge, business acumen, and analytical skills to identify opportunities for improvement

- Industrial engineers apply systems thinking to consider the entire system, including people, materials, equipment, and energy

- They use principles of engineering, statistics, and computer science to create models, simulations, and algorithms for analysis and optimization

- Industrial engineers work in a wide range of industries, including manufacturing, logistics, healthcare, and finance

Role and Responsibilities of Industrial Engineers

Industrial engineers play a critical role in organizations, working to improve the efficiency, productivity, and quality of operations. Their responsibilities may include analyzing production processes, designing new systems and facilities, and implementing quality control measures. They may also be involved in supply chain management, inventory control, and logistics, working to optimize the flow of materials, goods, and services. Additionally, industrial engineers may be responsible for conducting cost-benefit analyses, developing business cases for new projects, and implementing lean manufacturing principles to reduce waste and variability.

Industrial engineers use a variety of tools and techniques to perform their jobs, including computer-aided design (CAD) software, simulation modeling, and statistical process control (SPC). They may also work with other professionals, such as operations managers, quality engineers, and supply chain managers, to ensure that improvements are implemented effectively and sustainably. By applying their knowledge and skills, industrial engineers can help organizations to reduce costs, improve customer satisfaction, and increase competitiveness in the marketplace.

Subfields of Industrial Engineering

Industrial engineering is a diverse field, with several subfields that focus on specific areas of application. Some of the key subfields include manufacturing engineering, which focuses on the design and optimization of production systems; quality engineering, which emphasizes the development of quality control measures and inspection systems; and supply chain engineering, which involves the design and optimization of logistics and supply chain systems. Other subfields include human factors engineering, which focuses on the design of systems and interfaces that are safe, efficient, and easy to use; and operations research, which involves the use of advanced analytical methods to optimize complex systems and processes.

| Subfield | Description |

|---|---|

| Manufacturing Engineering | Design and optimization of production systems |

| Quality Engineering | Development of quality control measures and inspection systems |

| Supply Chain Engineering | Design and optimization of logistics and supply chain systems |

| Human Factors Engineering | Design of systems and interfaces that are safe, efficient, and easy to use |

| Operations Research | Use of advanced analytical methods to optimize complex systems and processes |

Education and Training for Industrial Engineers

Industrial engineers typically require a bachelor’s degree in industrial engineering or a related field, such as mechanical engineering, electrical engineering, or computer science. Coursework in industrial engineering programs may include classes in mathematics, statistics, computer science, and engineering, as well as specialized courses in areas such as manufacturing systems, quality control, and supply chain management. Many industrial engineers also pursue advanced degrees, such as master’s or Ph.D.s, which can provide additional training and qualifications for leadership roles or specialized positions.

In addition to formal education, industrial engineers may also receive training and certification through professional organizations, such as the Institute of Industrial and Systems Engineers (IISE) or the Society of Manufacturing Engineers (SME). These organizations offer a range of resources, including conferences, workshops, and online courses, to help industrial engineers stay current with the latest developments in the field. By combining formal education with ongoing training and professional development, industrial engineers can build the skills and knowledge they need to succeed in this exciting and rewarding field.

Career Paths for Industrial Engineers

Industrial engineers can pursue a wide range of career paths, from traditional roles in manufacturing and logistics to emerging fields such as data analytics and artificial intelligence. Some industrial engineers may work as consultants, helping organizations to improve their operations and implement new technologies. Others may work in leadership roles, such as operations managers or plant managers, overseeing the daily activities of manufacturing facilities or logistics operations. With their strong analytical skills and ability to think creatively, industrial engineers are also well-suited to careers in research and development, where they can work on designing and testing new products and systems.

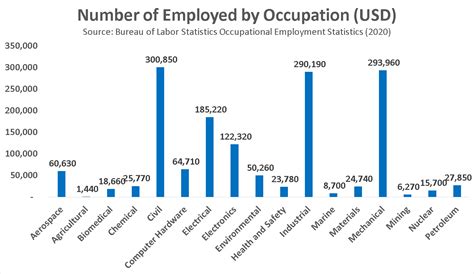

According to the Bureau of Labor Statistics (BLS), the median annual salary for industrial engineers in the United States is around $87,000, although salaries can range from around $50,000 to over $130,000 depending on factors such as location, industry, and level of experience. With their strong technical skills and ability to drive business results, industrial engineers are in high demand, and can expect to enjoy strong career prospects and opportunities for advancement in the years to come.

What is the role of an industrial engineer in a manufacturing organization?

+Industrial engineers in manufacturing organizations are responsible for designing and optimizing production systems, implementing quality control measures, and improving efficiency and productivity.

What skills and knowledge are required to become an industrial engineer?

+Industrial engineers require strong technical skills, including knowledge of mathematics, statistics, and engineering principles. They must also have excellent analytical and problem-solving skills, as well as the ability to communicate effectively with stakeholders.

What are some of the emerging trends and technologies in industrial engineering?

+Some of the emerging trends and technologies in industrial engineering include data analytics, artificial intelligence, and the Internet of Things (IoT). These technologies are enabling industrial engineers to design and optimize more complex systems, and to make more informed decisions using data-driven insights.