Styrofoam, commonly referred to as Styro, is a type of plastic that is widely used in packaging, insulation, and other applications. However, it is not biodegradable and can take hundreds of years to decompose, contributing to environmental pollution and waste management issues. Recycling Styrofoam is crucial to reduce its impact on the environment. Here are five ways to recycle Styrofoam, focusing on innovative methods and community-driven initiatives.

Understanding Styrofoam Recycling Challenges

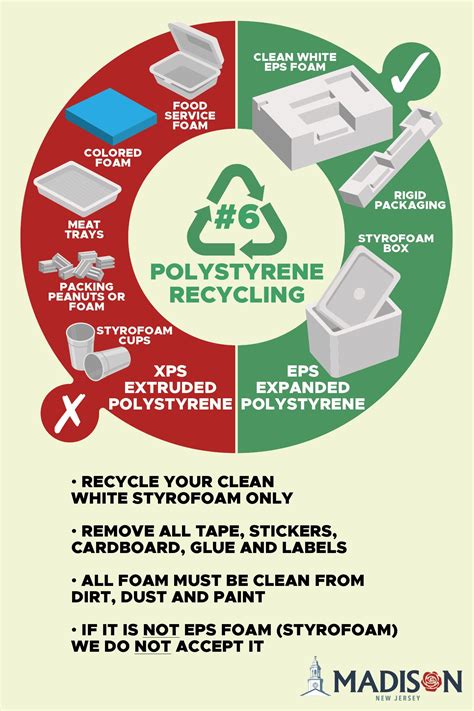

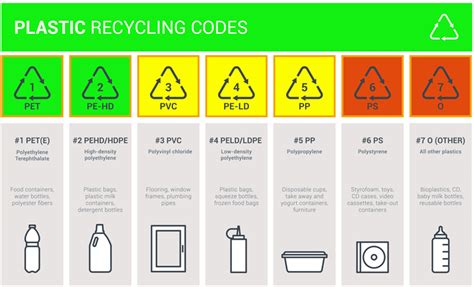

Styrofoam recycling faces several challenges, including the lack of specialized recycling facilities and the high cost of processing. However, with the advancement of technology and growing environmental awareness, new methods and initiatives are emerging to tackle these challenges. One of the primary concerns is the contamination of Styrofoam with other materials, such as food residue, tape, and plastic film, which can make it difficult to recycle. Therefore, it is essential to educate the public on the importance of proper Styrofoam disposal and recycling.

Key Points

- Styrofoam recycling is crucial for reducing environmental pollution and waste management issues.

- Specialized recycling facilities and high processing costs are significant challenges in Styrofoam recycling.

- Proper disposal and recycling of Styrofoam require public education and awareness.

- Innovative methods, such as densification and extrusion, are being developed to improve Styrofoam recycling efficiency.

- Community-driven initiatives, like drop-off programs and curbside collection, are essential for increasing Styrofoam recycling rates.

Densification: A Cost-Effective Method

Densification is a process that compresses Styrofoam into a dense, compact form, making it easier to transport and recycle. This method is cost-effective and can be done using specialized equipment. Densified Styrofoam can be used to manufacture new products, such as plastic lumber, decking, and fencing. According to the Environmental Protection Agency (EPA), densification can reduce the volume of Styrofoam by up to 90%, making it a highly efficient recycling method.

| Styrofoam Recycling Method | Volume Reduction |

|---|---|

| Densification | Up to 90% |

| Extrusion | Up to 70% |

| Compaction | Up to 50% |

Extrusion: Converting Styrofoam into New Products

Extrusion is a process that melts and reshapes Styrofoam into new products, such as plastic pellets, which can be used to manufacture a variety of items, including packaging materials, containers, and even clothing. This method is highly versatile and can be used to create a wide range of products. According to a study by the National Waste & Recycling Association, extrusion can help reduce greenhouse gas emissions by up to 70% compared to traditional manufacturing methods.

Drop-Off Programs: Community-Driven Initiatives

Drop-off programs are community-driven initiatives that allow residents to drop off their Styrofoam at designated locations, where it is then collected and recycled. These programs are essential for increasing Styrofoam recycling rates and raising public awareness about the importance of proper disposal. According to a survey by the Keep America Beautiful organization, 75% of participants in drop-off programs reported an increase in their recycling rates, highlighting the effectiveness of these initiatives.

Curbside Collection: Convenient and Accessible

Curbside collection is a convenient and accessible method of Styrofoam recycling, where residents can place their Styrofoam in a designated bin, and it is collected along with other recyclables. This method is highly effective in increasing recycling rates, as it eliminates the need for residents to transport their Styrofoam to a drop-off location. According to a study by the EPA, curbside collection can increase recycling rates by up to 30% compared to drop-off programs.

Specialized Recycling Facilities: The Future of Styrofoam Recycling

Specialized recycling facilities are dedicated to recycling Styrofoam and other types of plastic. These facilities use advanced technology to sort, clean, and process Styrofoam, making it possible to recycle a wide range of products. According to a report by the International Solid Waste Association, specialized recycling facilities can recycle up to 95% of Styrofoam, making them a critical component of a sustainable waste management system.

What are the benefits of Styrofoam recycling?

+The benefits of Styrofoam recycling include reducing environmental pollution, conserving natural resources, and decreasing greenhouse gas emissions. Recycling Styrofoam also helps to reduce waste management costs and promotes a more circular economy.

How can I participate in Styrofoam recycling programs?

+You can participate in Styrofoam recycling programs by dropping off your Styrofoam at designated locations, participating in curbside collection, or using specialized recycling facilities. You can also contact your local waste management agency to learn more about Styrofoam recycling programs in your area.

What are the challenges of Styrofoam recycling?

+The challenges of Styrofoam recycling include the lack of specialized recycling facilities, high processing costs, and contamination of Styrofoam with other materials. However, with the advancement of technology and growing environmental awareness, new methods and initiatives are emerging to tackle these challenges.

In conclusion, Styrofoam recycling is a critical component of sustainable waste management, and innovative methods like densification, extrusion, and community-driven initiatives are essential for increasing recycling rates. By understanding the challenges and benefits of Styrofoam recycling, we can work together to promote a more circular economy and reduce the environmental impact of this versatile material. As we move forward, it is essential to continue developing new technologies and initiatives that make Styrofoam recycling more efficient, accessible, and effective.

Meta Description: Learn about the importance of Styrofoam recycling and discover five innovative methods to recycle this versatile material, including densification, extrusion, and community-driven initiatives.