Surface Mount Devices (SMDs) have revolutionized the world of electronics by offering a more efficient, compact, and reliable way to manufacture electronic circuits. The shift from traditional through-hole components to SMDs has been significant due to their numerous advantages, including smaller size, lower production costs, and improved performance. However, working with SMDs requires specific techniques and tools to ensure successful assembly and repair. Here are five tips for working with SMDs, covering the essentials from preparation to the actual soldering process.

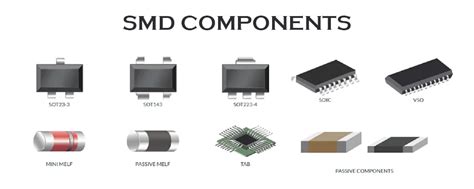

Understanding SMD Types and Specifications

Before starting any project involving SMDs, it’s crucial to understand the different types of SMD components and their specifications. SMDs come in a variety of packages, such as SOIC (Small Outline Integrated Circuit), TSSOP (Thin Shrink Small Outline Package), QFN (Quad Flat No-leads), and BGA (Ball Grid Array), among others. Each type has its unique characteristics, such as pin spacing, package size, and thermal dissipation requirements. Knowing the specifications of the components you are working with is essential for selecting the right tools and techniques for handling and soldering them. For instance, BGA components require specialized tools for rework due to their lack of visible leads.

Preparation is Key

Preparation is a critical step when working with SMDs. This includes having the right tools and materials, such as a soldering iron with a fine tip, a hot air gun or a rework station for more complex components, flux, and solder paste or wire. The workspace should be clean, well-lit, and preferably equipped with a microscope or a magnifying glass to help with the inspection and placement of small components. Additionally, using anti-static precautions is vital to prevent damage to sensitive components. This can be achieved by using an anti-static wrist strap, an anti-static mat, or working in an environment with controlled humidity and static protection.

| Tool | Description |

|---|---|

| Soldering Iron | A fine-tip soldering iron for precise soldering. |

| Hot Air Gun/Rework Station | For soldering and desoldering SMDs that require precise temperature control. |

| Flux | To improve solder flow and reduce oxidation. |

| Solder Paste/Wire | For making connections between components and the PCB. |

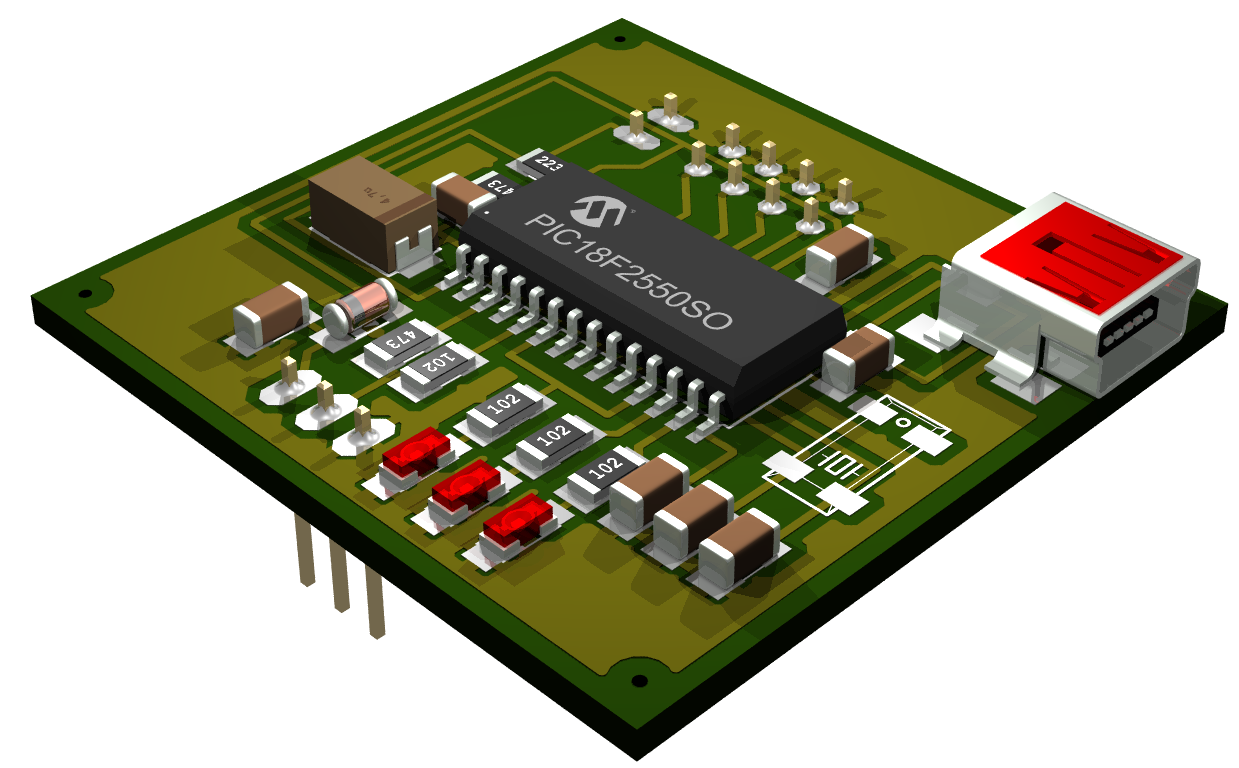

Soldering Techniques for SMDs

Soldering SMDs requires precision and the right technique. For most SMDs, applying a small amount of solder paste to the component’s pads on the PCB before placing the component is recommended. The component is then heated, either with a soldering iron for smaller components or a hot air gun for larger ones, until the solder melts and the component is securely attached. It’s essential to avoid applying too much heat, which can damage the component or the PCB. Practice and patience are key to mastering the soldering technique for SMDs.

Inspection and Repair

After soldering, inspecting the joints under a microscope or a magnifying glass is crucial to ensure that the solder joints are clean, have the right shape, and there are no signs of oxidation or solder bridges. For components that are difficult to inspect, such as BGAs, using X-ray inspection equipment may be necessary. Repairing SMDs can be challenging and often requires specialized tools and techniques. Desoldering wicks or pumps can be used for removing excess solder, and for more complex repairs, a rework station may be necessary.

Key Points

- Understanding the specifications and types of SMD components is essential for successful assembly and repair.

- Preparation, including having the right tools and a suitable workspace, is critical.

- Soldering techniques for SMDs require precision and the right amount of heat to avoid damaging components.

- Inspection after soldering is vital to ensure the quality of the solder joints.

- Repairing SMDs can be challenging and may require specialized tools and techniques.

In conclusion, working with SMDs requires a combination of the right tools, techniques, and patience. By understanding the different types of SMDs, preparing the workspace appropriately, mastering soldering techniques, inspecting solder joints carefully, and knowing how to repair defective solder joints, individuals can successfully work with SMDs in their electronic projects. Whether you are a professional in the electronics industry or a hobbyist, the ability to work with SMDs is a valuable skill that can open up a wide range of possibilities in electronic design and manufacturing.

What are the advantages of using SMDs over traditional through-hole components?

+SMDs offer several advantages, including smaller size, lower production costs, improved performance, and higher density on printed circuit boards (PCBs), making them ideal for compact and complex electronic designs.

How do I choose the right soldering iron tip for SMD work?

+Choosing the right soldering iron tip for SMD work involves selecting a tip that is fine enough to accurately solder small components without causing damage. Tips with a small radius (0.1mm to 0.5mm) are often preferred for precision SMD soldering.

What safety precautions should I take when working with SMDs?

+When working with SMDs, it’s essential to take safety precautions such as wearing an anti-static wrist strap to prevent static damage to components, using protective eyewear to prevent eye damage from solder splashes, and ensuring good ventilation to avoid inhaling solder fumes.