The role of an industrial engineer is multifaceted and critical in today's fast-paced, technology-driven manufacturing and service industries. Industrial engineers are responsible for designing, implementing, and optimizing systems, processes, and facilities to ensure efficient and effective production, while also ensuring the quality and safety of products and services. Their expertise spans a wide range of areas, including supply chain management, quality control, facilities planning, and human factors engineering. With a focus on continuous improvement and problem-solving, industrial engineers play a vital role in enhancing organizational productivity and reducing costs.

Key Points

- Industrial engineers design and optimize systems, processes, and facilities to improve efficiency and reduce costs.

- They apply principles of engineering, mathematics, and physics to develop and implement solutions.

- Industrial engineers work in a variety of industries, including manufacturing, healthcare, and logistics.

- Their role involves collaboration with cross-functional teams, including production, quality, and maintenance.

- Continuous learning and professional development are essential for industrial engineers to stay up-to-date with the latest technologies and methodologies.

Primary Responsibilities and Skills

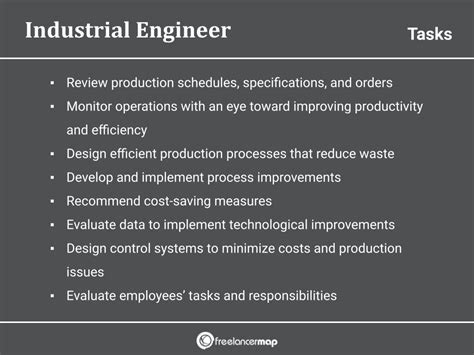

Industrial engineers are tasked with analyzing and optimizing production systems, supply chains, and logistics to achieve maximum efficiency and minimize waste. This involves applying principles of engineering, mathematics, and physics to develop and implement solutions. They must possess strong analytical and problem-solving skills, as well as excellent communication and interpersonal skills to effectively collaborate with cross-functional teams. Additionally, industrial engineers must be proficient in a range of software tools, including simulation modeling, statistical analysis, and computer-aided design (CAD).

Technical Skills and Tools

Some of the key technical skills and tools used by industrial engineers include:

- Simulation modeling software, such as Simio or Arena

- Statistical analysis tools, such as Minitab or R

- CAD software, such as Autodesk or SolidWorks

- Supply chain management software, such as SAP or Oracle

- Quality control tools, such as Six Sigma or Lean

| Industry | Job Title | Median Salary |

|---|---|---|

| Manufacturing | Industrial Engineer | $85,000 |

| Healthcare | Industrial Engineer | $80,000 |

| Logistics | Industrial Engineer | $75,000 |

Education and Certification

Industrial engineers typically hold a bachelor’s degree in industrial engineering or a related field, such as mechanical engineering or operations research. Many industrial engineers also pursue advanced degrees, such as master’s or doctoral degrees, to specialize in a particular area or to advance their careers. Certification is also available through organizations such as the Institute of Industrial and Systems Engineers (IISE) or the American Society for Quality (ASQ), and can demonstrate expertise and commitment to the field.

Career Path and Advancement

Industrial engineers can pursue a variety of career paths, including:

- Operations management

- Supply chain management

- Quality control

- Facilities planning

- Management consulting

What is the typical salary range for an industrial engineer?

+The typical salary range for an industrial engineer is between $60,000 and $100,000 per year, depending on factors such as location, industry, and level of experience.

What skills are most important for an industrial engineer to possess?

+Industrial engineers should possess strong analytical and problem-solving skills, as well as excellent communication and interpersonal skills. They should also be proficient in a range of software tools, including simulation modeling, statistical analysis, and computer-aided design (CAD).

What is the outlook for job growth in the field of industrial engineering?

+The Bureau of Labor Statistics predicts that employment of industrial engineers will grow 10% from 2020 to 2030, which is faster than the average for all occupations.

In conclusion, the role of an industrial engineer is critical in today’s fast-paced, technology-driven manufacturing and service industries. With a focus on continuous improvement and problem-solving, industrial engineers play a vital role in enhancing organizational productivity and reducing costs. By possessing strong analytical and problem-solving skills, as well as excellent communication and interpersonal skills, industrial engineers can pursue a variety of career paths and advance their careers in this exciting and rewarding field.