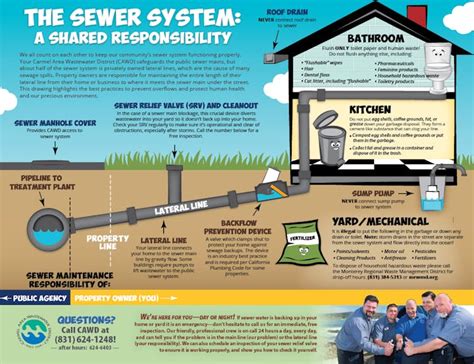

Industrial sewers are a crucial component of any manufacturing or industrial facility, serving as the primary means of wastewater disposal. Proper maintenance and management of these systems are essential to prevent environmental hazards, ensure compliance with regulatory requirements, and maintain operational efficiency. In this article, we will delve into five industrial sewer tips that can help facility managers and operators optimize their wastewater management practices.

Key Points

- Regular inspection and maintenance of industrial sewer systems to prevent clogs and blockages

- Implementation of effective wastewater treatment technologies to minimize environmental impact

- Proper training of personnel on industrial sewer operation and maintenance best practices

- Integration of industrial sewer management with overall facility operations to enhance efficiency

- Continuous monitoring and adaptation to changing regulatory requirements and industry standards

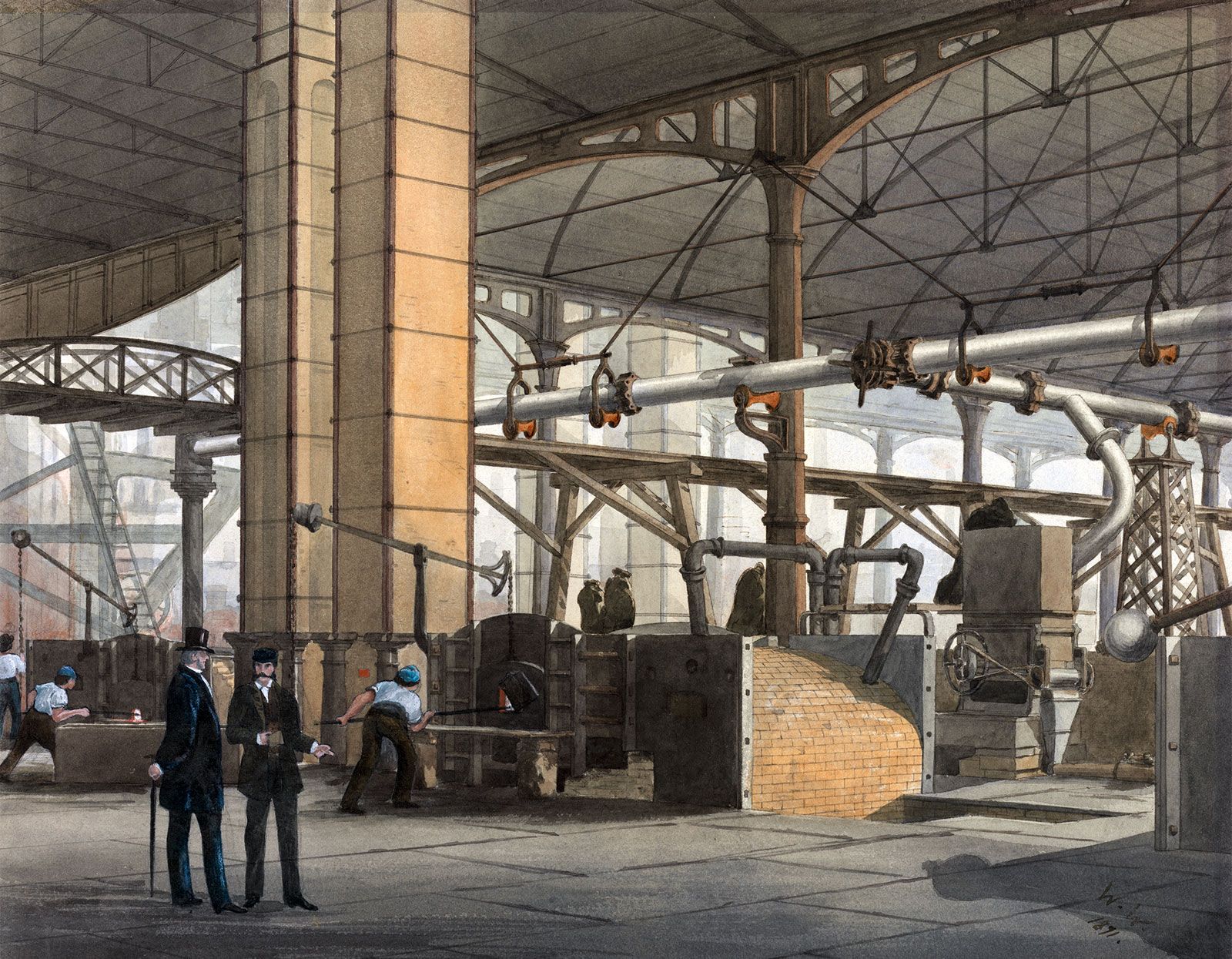

Industrial Sewer System Design and Installation

A well-designed and properly installed industrial sewer system is the foundation of effective wastewater management. Facility managers should work with experienced engineers and contractors to ensure that the system is tailored to the specific needs of the facility, taking into account factors such as wastewater volume, flow rate, and composition. Regular inspections and testing should be conducted to identify potential issues before they become major problems. For instance, a study by the Environmental Protection Agency (EPA) found that 40% of industrial sewer systems in the United States experience some form of failure or blockage each year, resulting in significant environmental and economic costs.

Wastewater Treatment Technologies

The choice of wastewater treatment technology is critical in minimizing the environmental impact of industrial sewer systems. Biological treatment methods, such as activated sludge processes, are commonly used to remove organic pollutants from wastewater. However, advanced treatment technologies, such as membrane bioreactors (MBRs) and UV disinfection, may be necessary to meet stricter regulatory requirements or to achieve higher levels of water quality. Facility managers should consult with wastewater treatment experts to determine the most effective and cost-efficient treatment solutions for their specific needs. According to a report by the National Association of Clean Water Agencies, the use of MBR technology can result in up to 90% reduction in wastewater pollution.

| Wastewater Treatment Technology | Removal Efficiency |

|---|---|

| Activated Sludge Process | 80-90% |

| Membrane Bioreactor (MBR) | 95-99% |

| UV Disinfection | 99.9% |

Industrial Sewer Operation and Maintenance

Proper operation and maintenance of industrial sewer systems are essential to prevent clogs, blockages, and other issues that can lead to environmental hazards and regulatory noncompliance. Facility managers should develop and implement comprehensive maintenance programs that include regular inspections, cleaning, and repairs. Training programs should also be provided to personnel to ensure that they are aware of best practices and procedures for operating and maintaining the industrial sewer system. According to a study by the American Society of Civil Engineers, 70% of industrial sewer system failures are attributed to inadequate maintenance and operation.

Integration with Facility Operations

Industrial sewer management should be integrated with overall facility operations to enhance efficiency and minimize costs. Facility managers should work with production staff to synchronize wastewater generation with treatment capacity, reducing the likelihood of overflows and other issues. Real-time monitoring systems can also be implemented to track wastewater flow rates, water quality, and treatment performance, enabling prompt response to any issues that may arise. By integrating industrial sewer management with facility operations, managers can optimize wastewater treatment, reduce energy consumption, and improve overall facility performance.

What are the most common causes of industrial sewer system failures?

+The most common causes of industrial sewer system failures include inadequate maintenance, improper design and installation, and excessive wastewater generation. Other factors, such as corrosion, erosion, and blockages, can also contribute to system failures.

How can facility managers optimize their industrial sewer systems to achieve regulatory compliance and minimize environmental impact?

+Facility managers can optimize their industrial sewer systems by implementing effective wastewater treatment technologies, developing and implementing comprehensive maintenance programs, and integrating industrial sewer management with overall facility operations. Regular inspections, monitoring, and training programs can also help to prevent issues and ensure regulatory compliance.

What are the benefits of using advanced wastewater treatment technologies, such as membrane bioreactors (MBRs) and UV disinfection?

+The benefits of using advanced wastewater treatment technologies, such as MBRs and UV disinfection, include higher removal efficiencies, improved water quality, and reduced environmental impact. These technologies can also help facility managers to meet stricter regulatory requirements and achieve higher levels of wastewater reuse and recycling.

In conclusion, effective industrial sewer management requires a comprehensive approach that incorporates proper system design and installation, effective wastewater treatment technologies, regular maintenance and operation, and integration with overall facility operations. By following these five industrial sewer tips and staying up-to-date on the latest technologies and best practices, facility managers can optimize their industrial sewer systems to achieve regulatory compliance, minimize environmental impact, and reduce costs. As the wastewater management landscape continues to evolve, it is essential for facility managers to remain vigilant and adapt to changing regulatory requirements, industry standards, and technological advancements to ensure the long-term sustainability of their operations.