Casting, a fundamental process in various industries such as manufacturing, arts, and entertainment, involves shaping a material into a desired form. The techniques and materials used can vary significantly depending on the application, ranging from metals and alloys in engineering to plaster and resin in sculpting. Understanding the different methods of casting is crucial for achieving the desired outcome, whether it's producing a precise mechanical component or creating a detailed work of art. This article will delve into five distinct ways of casting, exploring their processes, applications, and the unique challenges each presents.

Key Points

- Sand casting is a versatile method used for producing complex metal parts with high precision.

- Investment casting, also known as lost-wax casting, is ideal for creating detailed and intricate components.

- Die casting is a high-volume process that offers rapid production of parts with a high degree of accuracy.

- Plaster casting is commonly used in art and sculpture for creating molds and replicas of objects.

- Continuous casting is a highly efficient method used in the steel industry for producing semi-finished products.

Sand Casting

Sand casting is one of the oldest and most widely used casting techniques. It involves creating a mold from sand, into which the molten metal is poured. The sand is typically mixed with a binder to increase its strength and stability. Once the metal has solidified, the sand mold is broken away, revealing the cast part. Sand casting is versatile and can be used to produce parts with complex geometries. However, it can be a labor-intensive process, and the surface finish of the cast parts may require additional machining. Key applications include engine blocks, machine tool bases, and other large metal components where complexity and strength are critical.

Advantages and Limitations of Sand Casting

The primary advantage of sand casting is its flexibility and the ability to produce parts in a wide range of sizes and complexities. However, the process can be time-consuming, and achieving high precision and surface finish can be challenging. Pattern making, the process of creating the original model from which the sand mold is made, requires significant skill and can be a bottleneck in the production process. Despite these challenges, sand casting remains a vital technique in modern manufacturing due to its adaptability and cost-effectiveness for low-to-medium volume production runs.

Investment Casting

Investment casting, or lost-wax casting, is a precision casting process that can produce parts with intricate details and high accuracy. The process begins with creating a wax pattern of the desired part, which is then coated with a refractory material to form a shell. The wax is melted out, and the shell is filled with molten metal. After the metal has solidified, the shell is broken away, revealing the cast part. Investment casting is used in aerospace, medical, and automotive industries for parts that require high precision and surface finish, such as turbine blades and medical implants.

Applications of Investment Casting

The unique advantage of investment casting lies in its ability to produce parts with complex internal structures and thin walls, making it ideal for applications where weight reduction and precision are critical. The process allows for a high degree of customization, enabling the production of parts with specific properties tailored to their intended use. However, the cost of investment casting can be higher than other methods, particularly for small production volumes, due to the complexity of the process and the materials involved.

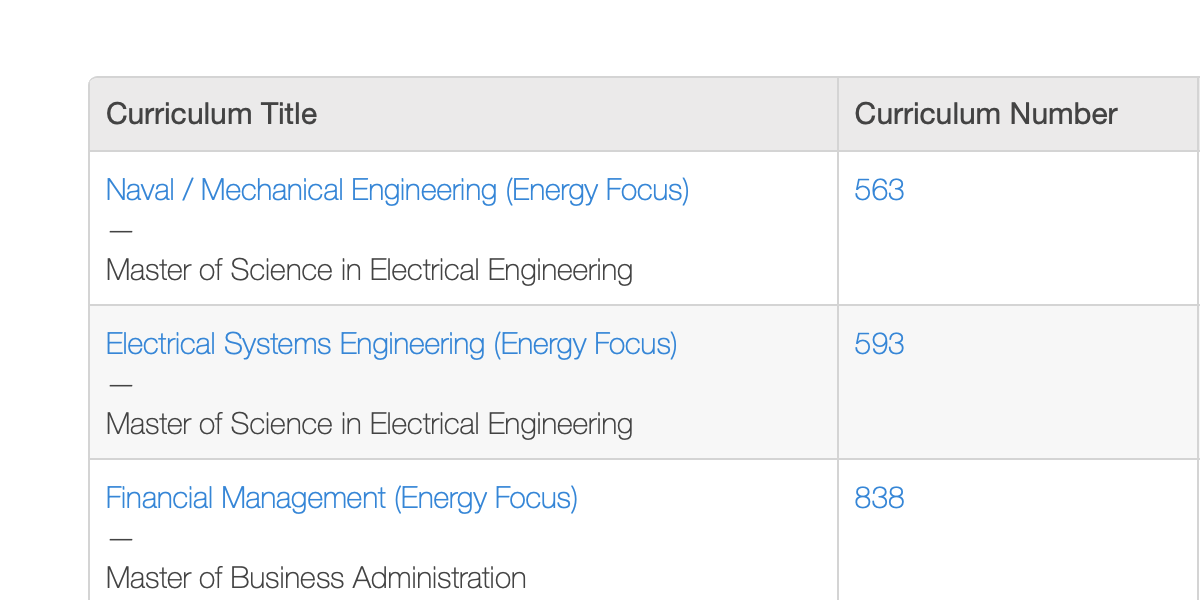

| Casting Method | Primary Application | Key Advantage |

|---|---|---|

| Sand Casting | Engine Components | Versatility and Cost-Effectiveness |

| Investment Casting | Aerospace and Medical Parts | High Precision and Detail Capability |

| Die Casting | Consumer Electronics and Automotive Parts | High Volume Production and Rapid Tooling |

| Plaster Casting | Artistic Sculptures and Replicas | Detail Preservation and Aesthetic Appeal |

| Continuous Casting | Steel Production | Efficiency and High-Volume Output |

Die Casting

Die casting is a high-pressure casting process that involves forcing molten metal into a mold cavity. The mold, or die, is made of steel and is designed to produce parts with high accuracy and surface finish. Die casting is commonly used for producing parts in high volumes, such as zinc and aluminum alloys, and is particularly suited for applications where the part needs to have a smooth surface and precise dimensions, such as in consumer electronics and automotive components.

Die Casting Process and Applications

The die casting process allows for rapid production cycles and can achieve high levels of precision and consistency. However, the initial cost of creating the die can be high, making it more suitable for large production volumes. The choice of alloy is also critical, as it affects the part’s properties and the ease of casting. Post-casting treatments, such as machining and surface coating, may be necessary to achieve the desired properties and appearance of the final product.

Plaster Casting

Plaster casting is a technique used primarily in the arts for creating sculptures and replicas. The process involves creating a mold from plaster, into which a liquid material, such as resin or plaster, is poured. Once set, the cast object is removed from the mold, revealing a detailed and often delicate structure. Plaster casting is valued for its ability to capture fine details and is commonly used in restoration work and the production of architectural models.

Applications and Considerations of Plaster Casting

Plaster casting offers a unique combination of detail preservation and aesthetic appeal, making it an indispensable technique in artistic and architectural applications. However, the process can be sensitive to environmental conditions, such as humidity and temperature, which can affect the quality of the cast. Mold making is a critical step in plaster casting, requiring a high degree of skill to ensure that the mold accurately captures the details of the original object and can withstand the casting process.

Continuous Casting

Continuous casting is a process used in the steel industry to produce semi-finished products such as blooms, billets, and slabs. The process involves pouring molten steel into a continuous mold, where it solidifies into a long, thin strand. The strand is then cut into sections of the desired length. Continuous casting offers high efficiency and productivity, making it a cornerstone of modern steel production. It allows for the continuous production of high-quality steel products with consistent properties, which is essential for downstream applications such as rolling and forging.

Efficiency and Product Quality in Continuous Casting

The efficiency of continuous casting stems from its ability to produce steel continuously, without the need for individual molds or extensive post-casting processing. The process also enables tight control over the chemical composition and microstructure of the steel, which is critical for achieving specific properties such as strength, ductility, and resistance to corrosion. However, the initial investment in setting up a continuous casting facility can be substantial, and the process requires careful monitoring and control to ensure the quality of the products and the safety of the operation.

What are the primary considerations when selecting a casting method?

+The choice of casting method depends on factors such as the part's size, complexity, material, and the desired surface finish, as well as considerations of cost, production volume, and lead time.

How does the choice of casting material affect the final product?

+The casting material influences the part's mechanical properties, such as strength, durability, and resistance to corrosion, as well as its aesthetic appearance and potential for post-casting treatments.

What role does mold design play in the casting process?

+Mold design is critical in casting, as it determines the final shape and quality of the part. A well-designed mold must balance factors such as material flow, cooling rates, and dimensional accuracy to produce parts that meet the required specifications.

In conclusion, the choice of casting method is a critical decision that affects the quality, cost, and production efficiency of the final product. Each of the five casting methods discussed—sand casting, investment casting, die casting, plaster casting, and continuous casting—offers unique advantages and is suited to specific applications. By understanding the principles, advantages, and limitations of these techniques, manufacturers and artists can select the most appropriate method for their needs, ensuring the production of high-quality parts that meet precise specifications and requirements.