The role of an airplane mechanic, also known as an aircraft maintenance technician, is crucial for ensuring the safety and airworthiness of aircraft. These professionals are responsible for performing routine maintenance, repairs, and inspections on aircraft to prevent accidents and minimize downtime. The job requires a strong foundation in mechanics, electronics, and aerodynamics, as well as excellent problem-solving skills and attention to detail. Airplane mechanics work on various types of aircraft, including commercial airliners, private planes, and military aircraft, and may specialize in specific areas such as engine repair, avionics, or airframe maintenance.

A typical day for an airplane mechanic involves conducting inspections, diagnosing problems, and performing repairs and maintenance tasks. They may work on aircraft systems such as engines, fuel systems, electrical systems, and hydraulic systems, and must be familiar with a wide range of tools and equipment, including diagnostic software and specialized testing devices. Airplane mechanics must also be able to read and interpret technical manuals, blueprints, and other documentation to ensure that repairs and maintenance are performed correctly and in accordance with regulatory requirements.

Key Points

- Airplane mechanics perform routine maintenance, repairs, and inspections on aircraft to ensure safety and airworthiness.

- The job requires a strong foundation in mechanics, electronics, and aerodynamics, as well as excellent problem-solving skills and attention to detail.

- Airplane mechanics work on various types of aircraft, including commercial airliners, private planes, and military aircraft, and may specialize in specific areas such as engine repair or avionics.

- The role involves conducting inspections, diagnosing problems, and performing repairs and maintenance tasks, and requires familiarity with a wide range of tools and equipment.

- Airplane mechanics must be able to read and interpret technical manuals, blueprints, and other documentation to ensure that repairs and maintenance are performed correctly and in accordance with regulatory requirements.

Airplane Mechanic Responsibilities

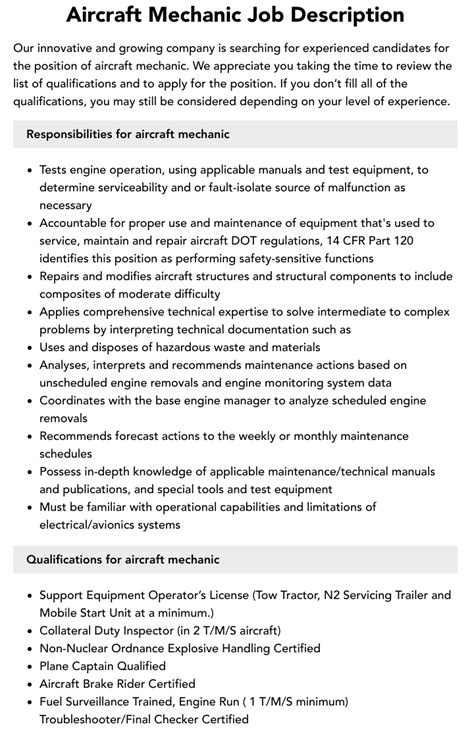

Airplane mechanics are responsible for a wide range of tasks, including conducting routine inspections and maintenance, diagnosing and repairing problems, and performing modifications and upgrades to aircraft systems. They must also be able to troubleshoot complex problems and develop effective solutions, and may work with other maintenance personnel, such as inspectors and engineers, to ensure that aircraft are airworthy and compliant with regulatory requirements.

In addition to their technical responsibilities, airplane mechanics must also be able to communicate effectively with pilots, other maintenance personnel, and regulatory officials, and must be able to document their work accurately and efficiently. They may work in a variety of settings, including airports, hangars, and repair stations, and may be required to work at heights, in confined spaces, or in other challenging environments.

Airplane Mechanic Specializations

There are several specializations within the field of airplane mechanics, including airframe mechanics, powerplant mechanics, and avionics technicians. Airframe mechanics work on the structural components of aircraft, such as the fuselage, wings, and control surfaces, and may perform tasks such as repairing cracks and corrosion, replacing worn or damaged parts, and applying protective coatings. Powerplant mechanics, on the other hand, work on aircraft engines and propellers, and may perform tasks such as overhauling engines, replacing engine components, and adjusting propeller pitch.

Avionics technicians specialize in the electrical and electronic systems of aircraft, including navigation, communication, and flight control systems. They may perform tasks such as troubleshooting electrical problems, installing new avionics equipment, and testing and calibrating systems to ensure that they are functioning properly.

| Airplane Mechanic Specialization | Description |

|---|---|

| Airframe Mechanic | Works on structural components of aircraft, such as fuselage, wings, and control surfaces. |

| Powerplant Mechanic | Works on aircraft engines and propellers, performing tasks such as overhauling engines and replacing engine components. |

| Avionics Technician | Specializes in electrical and electronic systems of aircraft, including navigation, communication, and flight control systems. |

Airplane Mechanic Education and Training

To become an airplane mechanic, you typically need to complete a training program approved by the Federal Aviation Administration (FAA) and obtain a mechanic’s certificate with an airframe and/or powerplant rating. These programs are usually offered at vocational schools, community colleges, or specialized aviation schools, and may include coursework in subjects such as aircraft systems, materials and processes, and federal regulations.

In addition to formal training, airplane mechanics must also complete ongoing education and training to stay current with new technologies and regulatory requirements. This may include attending seminars and workshops, completing online courses, and participating in on-the-job training programs.

Airplane Mechanic Certification

The FAA requires airplane mechanics to be certified, and offers several different types of certification, including the airframe mechanic certificate, the powerplant mechanic certificate, and the inspection authorization certificate. To become certified, you must meet the FAA’s eligibility requirements, which include being at least 18 years old, being able to read, speak, write, and understand English, and having a high school diploma or equivalent.

You must also complete a training program approved by the FAA and pass a series of written and practical exams to demonstrate your knowledge and skills. Certification is valid for a certain period, usually 24 months, and must be renewed by completing a recurrent training program and passing a recurrent exam.

What is the average salary of an airplane mechanic?

+The average salary of an airplane mechanic varies depending on factors such as location, experience, and type of aircraft worked on. However, according to the Bureau of Labor Statistics, the median annual salary for aircraft mechanics and service technicians was $62,920 in May 2020.

What are the working conditions like for an airplane mechanic?

+Airplane mechanics typically work in hangars, repair stations, or on airfields, and may be required to work at heights, in confined spaces, or in other challenging environments. They may also be exposed to noise, vibration, and hazardous materials, and must take precautions to protect themselves from injury.

What are the prospects for advancement as an airplane mechanic?

+Airplane mechanics with experience and specialized skills may have opportunities for advancement to supervisory or management positions, or may choose to start their own repair businesses. They may also have opportunities to work on a variety of different types of aircraft, or to specialize in a particular area such as avionics or engine repair.

As the demand for air travel continues to grow, the need for skilled airplane mechanics will only increase. If you’re interested in a challenging and rewarding career in aviation, becoming an airplane mechanic may be the perfect choice for you. With the right training, certification, and experience, you can build a successful and fulfilling career in this exciting field.